Coconut Product Processes

Coconut Anatomy

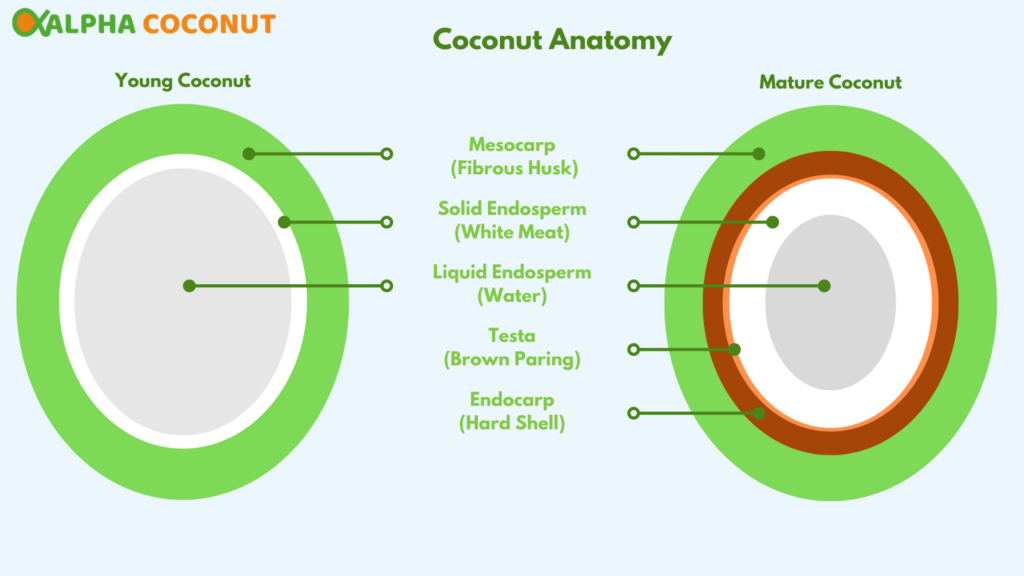

To understand coconut product processes, it is important to consider the anatomy of a coconut. A coconut, known scientifically as Cocos nucifera, is a remarkable fruit recognised for its distinct structure and versatile uses. The main parts of a coconut include the fibrous husk, known as the mesocarp, and the hard shell or endocarp, that encases the seed. The mesocarp is made up of coir, a fibrous husk that serves a protective function and can be used in various products like ropes, mats, and brushes. Once the husk is removed, one encounters the hard, woody shell that holds the seed and is typically characterized by its three “eyes” or germination pores, which are vulnerable points that allow for sprouting. Inside the shell lies the endosperm, which has two elements: the Coconut Meat, or Copra, which is rich in oil and provides a creamy texture, and Coconut Water, a refreshing liquid that is often enjoyed as a beverage. Coconut Meat is white and fibrous and covered by a thin skin of Testa (Paring). The White Meat provides a versatile ingredient in various culinary applications. Parings are used to produce Paring Oil, while the coconut water is sought after for its hydrating properties and is packed with electrolytes. Together, these components of a coconut demonstrate its unique adaptability and relevance across culinary, cosmetic, and household applications.

Coconut Product Process Flow

We highlight the coconut product processes to aid understanding on how each coconut product category is produced, from the different starting materials to the finished product.

Coconut Product Processes

Copra

Copra is derived from the white flesh removed from coconuts once they are cracked open and the shell removed. This flesh is then dried either by sun-drying or for industrial volumes by using a specialised drying machine. Once dried, the copra is then pressed to extract the oil. This process is done by mechanical pressing, or through other methods such as solvent extraction or expeller pressing.

RBD Oil

The crude Coconut Oil expelled from Copra is first refined and filtered to remove impurities like free fatty acids, gums, and pigments. Bleaching follows, where the oil is treated with activated carbon to remove any remaining colour and odour, leaving it a pale, clear hue. Finally, deodorisation takes place, under high heat and vacuum conditions to eliminate volatile compounds responsible for undesirable odours.

MCT Oil

RBD Oil undergoes a further refining process called fractionation, where it is heated and chilled to separate different components based on their melting points. Through this method, the Medium Chain Triglycerides can be separated from the Long Chain Triglycerides and isolated as a clear liquid. To enhance purity and eliminate impurities, the liquid undergoes further distillation and filtration processes.

MCT Powder

To create a powdered form, the liquid MCT oil is combined with a carrier, such as maltodextrin, tapioca fibre or powdered cellulose, and then spray-dried. This process involves spraying a fine mist of the MCT oil and carrier mixture into a hot chamber, where the moisture evaporates, leaving behind a dry powder. The resulting coconut MCT powder is a stable and convenient way to consume MCTs.

Charcoal

Coconut Shells are cleaned and dried to remove any moisture before being heated in special kilns at high temperatures of between 600 and 900 degrees Celsius. This process, called carbonisation, removes volatile compounds from the shells and leaves behind a pure carbon residue, coconut charcoal, that is highly porous with a large surface area, making it ideal as a fuel for cooking.

Activated Carbon

Charcoal undergoes activation by steam or activating agents such as potassium hydroxide or zinc chloride. The activating agent reacts with the carbon surface, creating numerous micropores, and a vast surface area. The activated carbon is then washed and dried to remove any residual impurities, resulting in a highly porous and adsorptive material to be used in water and air filtration.

Paring Oil

Once a coconut is deshelled, the resultant white meat sphere is covered by a thin brown layer of skin, which is ‘pared’ from the meat in strips to provide Parings. These strips are dried using a dehydrator until they become crispy and brittle, then pressed to extract Paring Oil from them. The resulting liquid is then filtered to remove any solid particles before being bottled and sold as Coconut Paring Oil.

Milk & Cream

The white meat from the coconut is shredded and mixed with hot water to suspend the fat present in the grated pulp, creating a thick mixture known as coconut cream. The cream is then separated through a centrifugal process, resulting in two distinct layers: thicker cream and thinner coconut milk. Finally, the cream and milk undergo homogenisation and pasteurisation to extend their shelf life.

Milk Powder

Homogenised and pasteurised Coconut Milk is mixed with stabilisers and a carrier substrate and spray-dried to create a fine powder. During the spray-drying process, the liquid coconut milk is atomised into tiny droplets and rapidly dried in a hot airstream, which evaporates the moisture content. The resulting coconut milk powder is a concentrated and shelf-stable form of coconut milk.

Desiccated Coconut

Undried white coconut meat kernels go through a slicing and grating process that yields thin, uniform shreds. These shreds are then subjected to a drying process where hot air is circulated to remove moisture. This dehydration reduces the moisture content to less than 3% and pateurises the product. The dried shreds are then milled down into fine, granular particles of various sizes.

Virgin Coconut Oil

Virgin Coconut Oil is mainly produced by two different processes, both of which start with fresh white coconut meat. The ‘Dry Method’ involves mechanical expelling of VCO from ‘dry’ desiccated coconut. The second method, known as the ‘Wet Method’, involves the extraction of the VCO through the centrifuge of ‘wet’ coconut milk. Both methods result in a similar specification of VCO.

Water

After removing the fibrous husk, coconut water is extracted by drilling holes into the hard shell. The coconut water is then extracted and undergoes various filtration and centrifuge processes to remove any impurities before being pasteurised to extend its shelf life. This single-strength coconut water can be further processed through evaporation to produce a more viscous, concentrated coconut water.

Aminos

The manufacturing process of Coconut Aminos begins with the extraction of sap from the coconut blossoms, which is then fermented with sea salt and aged for several months. After fermentation, the liquid is filtered to remove any solids or impurities, resulting in a smooth and rich sauce. Finally, the coconut aminos are pasteurised to ensure food safety and extend shelf life.

Nectar

Coconut nectar is produced from coconut blossom sap, filtered to remove any impurities, and heated to kill any bacteria present. The sap is boiled in large vats, causing the sugars to caramelise until it reaches a thick, syrup-like consistency. Filtration then follows to remove any impurities and ensure a smooth texture. Finally, the coconut nectar undergoes pasteurisation before being packaged.

Vinegar

Once coconut sap has been collected, it is then filtered to remove any impurities. The filtered sap is transferred into large wooden barrels, sealed, and left to ferment for several months. During fermentation, naturally occurring yeasts and bacteria in the sap convert the sugars into alcohol, which is then converted into acetic acid through a second fermentation process.

Sugar

Coconut sugar production is a continuation of the nectar production process, whereby the sap is then heated on low heat until most of the water is evaporated, resulting in a thick syrup-like consistency. To crystallise the syrup, it undergoes a condensation process in which it is continually stirred and cooled until granules start forming. The solidified sugar is then sieved to separate any impurities.