Coconut Product Sources

Sourcing Locations

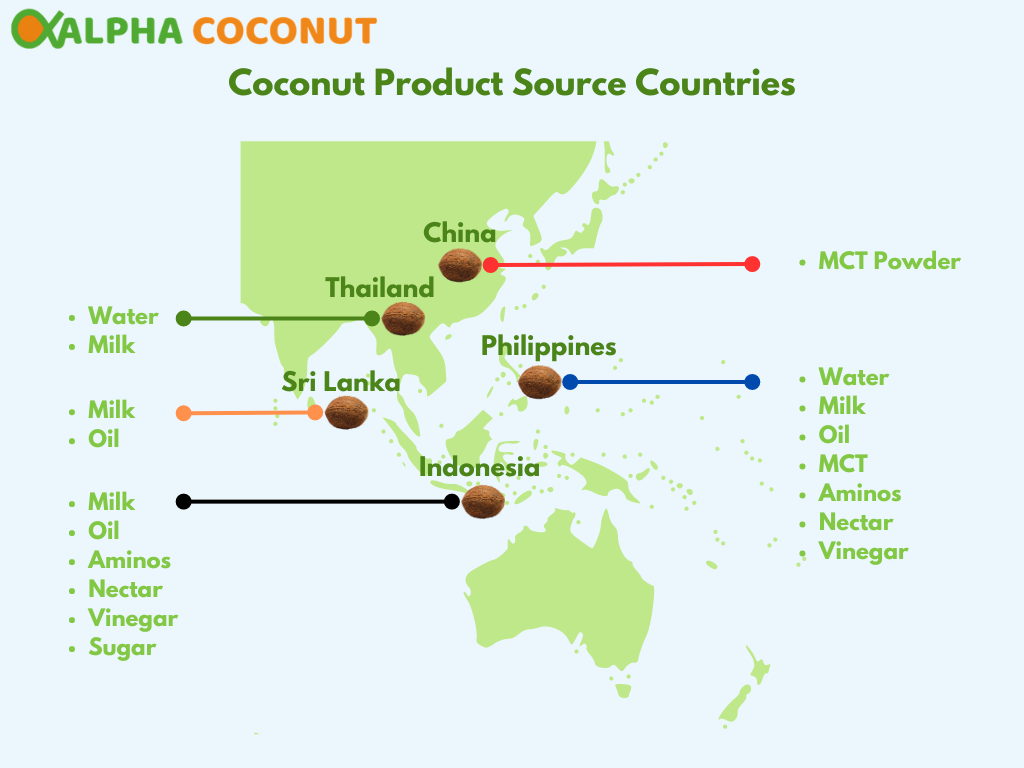

The five major coconut product sources in Asia are Indonesia, The Philippines, India, Sri Lanka, and Thailand.

- Indonesia is the top producer of coconuts worldwide, with vast plantations spread across its many islands.

- The Philippines follows closely behind, with a longstanding tradition of coconut cultivation dating back centuries.

- India boasts a diverse array of coconut varieties and utilizes every part of the coconut tree for various purposes.

- Sri Lanka is renowned for its high-quality coconuts and coconut-based products, such as virgin coconut oil and desiccated coconut.

- Lastly, Thailand rounds out the top five with its thriving coconut industry that supplies both domestic and international markets.

- Together, these countries account for a significant portion of global coconut product sources, contributing to various industries like food processing, cosmetics, and agriculture.

Alpha Coconut primarily partner with coconut product sources based in The Philippines, but in addition, we also work closely with producers in Indonesia, Thailand and Sri Lanka who have demonstrated records of quality and service at competitive prices, as well as from China for Spray Dried Powder products.

Production Facilities

Over the last decade, coconut producing facilities have evolved into more specialised facilities designed to process and transform raw coconuts into a variety of high-value products that meet increased customer standards. Alpha Coconut predominantly partner with producers that have invested in the key technology features that enable them to efficiently manage the complex processes involved in coconut processing, which includes:

- Automated Machinery: Modern coconut factories now utilise state-of-the-art automated equipment to streamline production processes. Machines are used for tasks such as optical sorting, ultrasonic testing, vacuum conveying, extraction of coconut milk and water, drying of coconut, and packaging finished products. This automation ensures consistent quality, increased efficiency, and reduced labor costs.

- Process Technology: Factories are now equipped with more advanced technologies to optimise coconut processing and extract maximum value. Most facilities apply the latest process technology related to Extraction, Filtering, Pasteurising, Centrifuges, Spray Drying, UHT Sterilisation, Aseptic Filling, and Oil Fractionation. In addition, humidity and temperature controlled environments are now commonplace.

- Multiple Production Lines: Coconut factories have now adopted a fully integrated approach, which often means having multiple production lines dedicated to different product categories. These lines can process coconuts into prime products including coconut milk, oil, liquid, water and powders, as well as their associated by-products.. The ability to handle diverse products allows factories to cater to a wider market and maximize revenue streams.

- Laboratory Facilities: In-house laboratories play a crucial role in maintaining product quality and ensuring microbiology, GMP and food safety standards are met.. Laboratories conduct rigorous testing to analyze coconut raw materials, monitor production processes, and verify product specifications. This helps factories comply with industry standards and regulatory requirements.

- Waste Management Systems: Coconut factories have robust waste management systems in place to minimize environmental impact. Coconut husks, shells, and other byproducts are processed and converted into useful materials, such as fuel pellets or activated carbon. This sustainable approach reduces waste and promotes circular economy practices.

Quality & Accreditation

In the coconut producing industry, adherence to stringent quality and accreditation requirements is paramount to ensure the safety, purity, and overall excellence of the final products. Alpha Coconut only work with producers who demonstrate a commitment to quality and food safety, and who adhere to compliance with international standards. Key aspects include:

- Good Manufacturing Practices (GMPs), which encompass hygiene, sanitation, and facility maintenance, ensuring cleanliness and minimizing contamination.

- Hazard Analysis and Critical Control Points (HACCP) is vital for identifying and controlling potential hazards throughout the production process, from raw material sourcing to packaging.

- Food Safety Management Systems (FSMS), like FSSC 22000, provide a comprehensive framework for managing food safety risks and demonstrating commitment to quality.

- International Standards for Food Safety (IFS), British Retail Consortium (BRC) are other globally recognized standards that enhance the credibility and marketability of coconut products.

- Organic Certification, often sought after by consumers, requires adherence to rigorous standards regarding farming practices, prohibiting synthetic pesticides and fertilizers.

- Fair Trade Certification ensures ethical sourcing, fair wages for farmers, and sustainable practices, fostering social responsibility.

- Traceability Systems are critical for tracking products throughout the supply chain, allowing for swift identification and response in case of issues.

- Halal and Kosher certifications are usually in place with companies adhering to strict guidelines set forth by Islamic and Jewish dietary laws, ensuring that products are prepared and processed in accordance with religious requirements.

- Quality Control throughout the production process, including microbiological, chemical, and sensory analysis, guarantees the product’s safety, quality, specification, and authenticity.